Perkins Brailler

Why the Perkins Brailler

- Best in Class: The most widely used mechanical braille writer in the world since its invention in 1951.

- Durability that Lasts for Decades: Metal casing, closed body architecture (limiting dust accumulation), and over 66 years of craftsmanship, resulting in a resilient product.

- Wide-ranging Usefulness: Wide paper length to accommodate complex math, note taking or other literacy activities.

- Reliable Support: One year warranty, repair service trainings and repair service centers throughout the world, ensuring that any problem with your product is resolved quickly.

Review our product comparisons guide

Features & Specs

- Full right and left margin adjustments to accommodate any paper size and line centering

- Round paper-feed knobs to enable easy paper loading and unloading

- Metal carrying handle

- Fast response time between typing and output

- Ergonomic Design for ease of typing

- Audible bell sound seven spaces before end of line

- Carriage release, full horizontal movement between margin stops

- Braille output conforms to American National Library Service for the Blind Size and Spacing Standard

- Includes user manual in both print and braille

- Includes leather dust cover

- Extension keys available for purchase

- Weight: 10.6 lb (4.8 kg)

- Paper size maximum: 11.5 x 14 in (29.2 x 35.6 cm)

- Recommended paper weight: 90 lb

- Key pad: Ergonomic design for ease of typing; Perkins keyboard standard

- Bell: Audible bell sounds 7 spaces before end of line

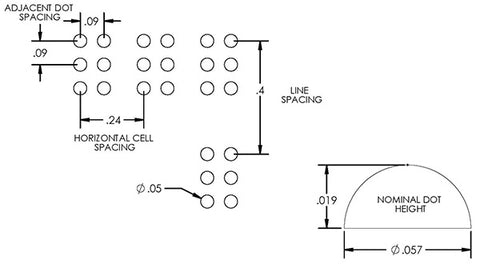

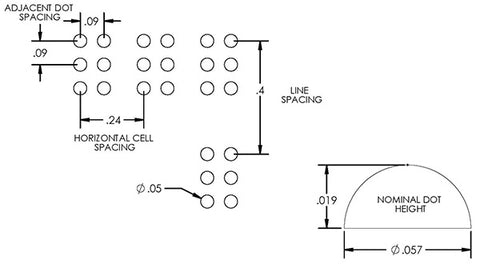

Braille produced by the Perkins Brailler conforms to the American National Library Service for the Blind Size and Spacing Standard.

- Dot height: .019 in (.5 mm)

- Dot diameter: .057 (1.4 mm)

- Dot spacing: .09 in (2.3 mm)

- Character spacing: .24 in (6 mm)

- Line spacing: .4 in (10 mm)

Product Care & Repair

The goal of keeping your brailler maintained is to keep it in good, working condition for many years to come. Braillers that are in near mint condition that are over 50 years old are in that good of condition because they were kept a good environment, and were maintained properly over the years.

Simple steps to keep your brailler in top working order:

- Store your brailler in a clean dry environment; humid and moist conditions can accelerate corrosion of the metal components.

- Clean the exterior of your brailler on a regular basis using a lint free cloth and soft bristle brush.

- Always keep your brailler covered when not in use; doing this will keep dust and debris from entering your brailler and avoid premature loss of motion (sluggish action) to the keys and carriage assembly.

- Send your brailler in to a certified Perkins repair center for regular service; we recommend every 3 – 5 years under normal use. For braillers that are heavily used or exposed to harsh environmental conditions, service more frequently.

Manuals & Downloads

User Manuals

- Perkins Brailler Manual in English

- Perkins Brailler Manual in Spanish

- Perkins Brailler Manual in German

- Perkins Brailler Manual in French

- Perkins Brailler Manual in Russian

FAQs

How do I load the paper into the brailler?

It is important to load the paper properly into the brailler, otherwise it will appear to be jammed and will not work.

- Move the carriage lever to its the left hand side of the brailler (starting position).

- Depress the line spacer until it will not depress anymore

- Pull the pressure roller levers towards you to open the drum

- Insert the paper from the back into the rounded roller drum and ensure that the paper is aligned to the left hand side of the brailer

- Push the pressure roller levers away from you to secure the paper

- Roll the paper all the way in till the feed knobs stop turning

- Hit the line spacer once

-

Begin to braille

I have heard the that Perkins Brailler is not made in the United States anymore. Is this true?

Almost all the components of the Perkins Brailler are designed, engineered and manufactured in the United States at the Howe Press plant on the Perkins School for the Blind's campus. The components are then assembled at the Howe Press plant or shipped to assembly plants in India and South Africa. Quality standards are developed and overseen by Howe Press and implemented equally across all Perkins Brailler locations. All braillers are guaranteed for one full year and we expect them to last for decades if properly maintained.